How Sanadi Technologies Enhanced Efficiency, Reduced Downtime, and Optimized Operations with AI-Powered Digital Twin Solutions

A leading manufacturing company faced significant challenges in equipment monitoring, predictive maintenance, and production efficiency. Frequent unplanned downtimes caused major disruptions in production, increasing operational costs and reducing output efficiency. The company relied on reactive maintenance strategies, leading to excessive repair costs and inefficient resource utilization. Additionally, the lack of real-time data insights made it difficult to optimize processes, allocate resources effectively, and identify potential failures before they occurred.

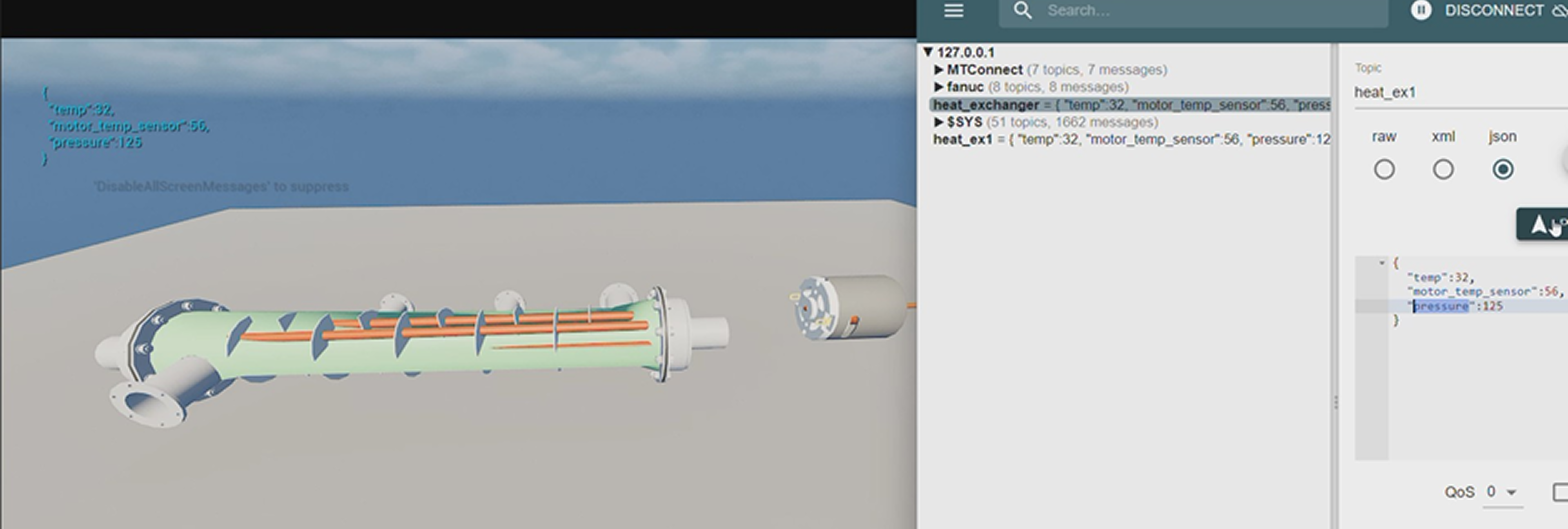

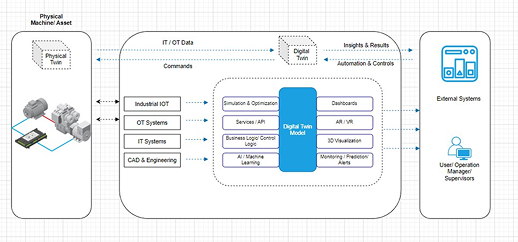

Sanadi Technologies implemented a Digital Twin system powered by Industrial IoT (IIoT) 4.0, AI-driven analytics, and cloud-based infrastructure. By deploying IIoT sensors on critical machinery, real-time performance data was collected and processed using AI-powered predictive maintenance models. A customized digital dashboard was developed, providing real-time visualization of equipment performance, energy usage, and potential failure risks. The system enabled remote monitoring through cloud integration, allowing managers to track key performance metrics from any location. Additionally, operational simulations were used to test process improvements before implementation, minimizing risks and optimizing resource allocation.

By implementing Digital Twin technology, the company significantly improved asset reliability, reduced downtime, and optimized production efficiency. With real-time monitoring and predictive analytics, maintenance costs were lowered, and decision-making became more data-driven. The solution not only enhanced operational efficiency but also laid the foundation for smart manufacturing and Industry 4.0 adoption, ensuring long-term sustainability and growth.

We assure you of the

at the most competitive rates !